Superior Systems for Bottle Handling and Bottle Palletizing

Plastic bottles, jars, containers, and their glass cousins are used in virtually every industry. MESH offers automation solutions for this industry in the area of packaging. Case packing of containers or bottles into corrugated boxes or in the stacking and palletizing of raw containers. Automation in this area has potential payback in improved labor utilization, increased throughput, quality improvements, and other returns typical to most automation projects.

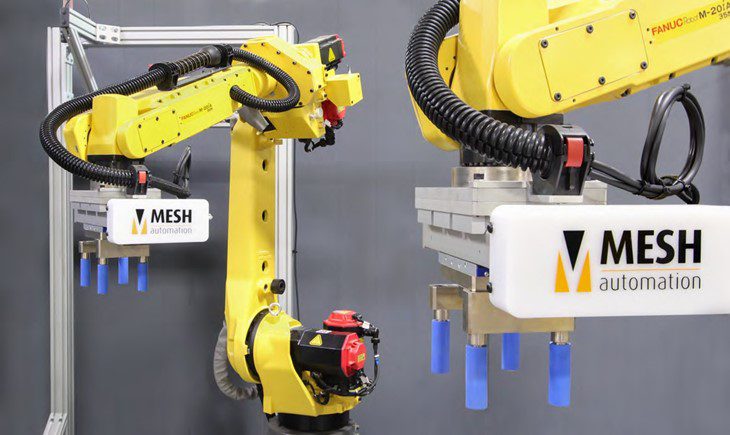

MESH Automation offers superior systems for bottle handling, robotic case packing, and robotic bottle palletizing to meet the automation needs in this industry.

Our bottle handling solutions include process conveyors in standard or food grade/pharma grade construction. We offer all conveyor accessories necessary to configure, sort, and feed bottles to the next automation piece of equipment such as a robotic case packer. MESH’s MACPac is ideally suited for highspeed case opening, packing, and sealing in a small footprint. No tool changeover and small batch size production are ideal for this machine.

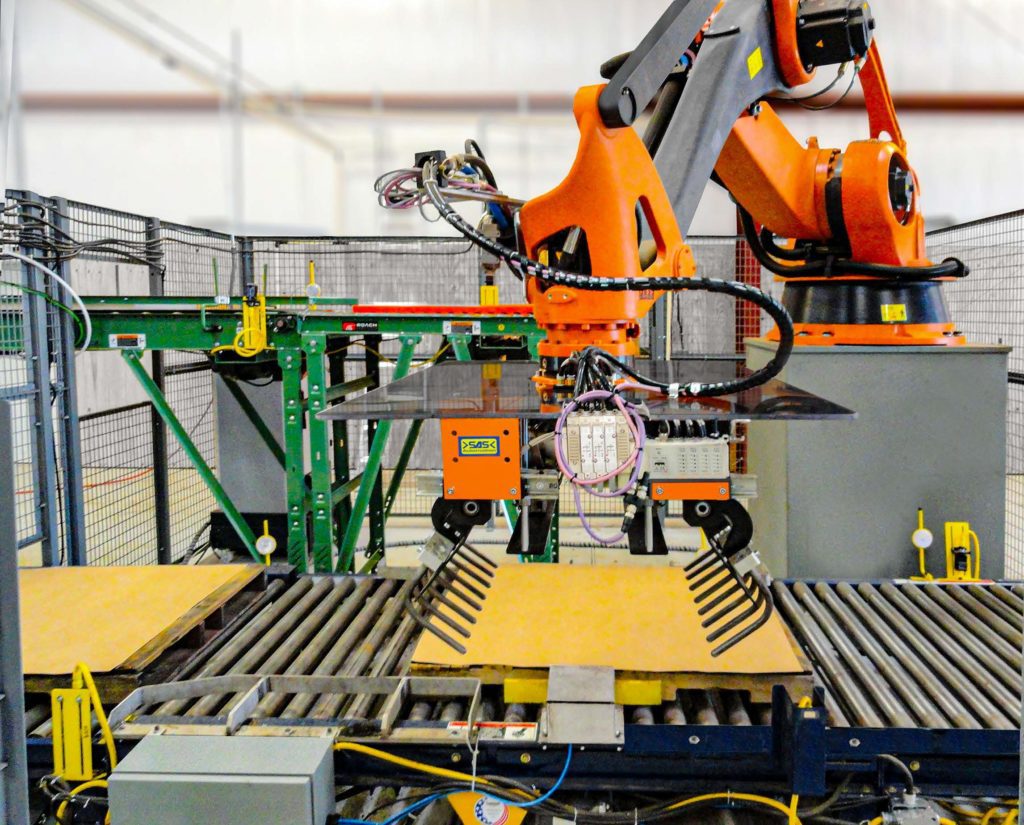

If no case packing is necessary and stacking or palletizing is next in line, MESH has their MACPal system ideally configured with a custom robotic end effector to robotically handle multiple bottle picks, slip sheets, pallets, and tier separators without a tool change.

Benefits of MESH Bottle Handling and Palletizing

MESH Automation Inc. specializes in designing and building engineered solutions for handling and palletizing glass and plastic bottles or containers. Our experienced teams create customized solutions to meet the needs of all our customers, regardless of whether they cater to the medical, pharmaceutical, life sciences, or food and beverage industries.

Some typical benefits of MESH solutions include:

- Highly efficient systems that increase production rates, improve labor utilization, improve job conditions (better ergonomics, less forklift interaction…) reduce product waste and improve product and package quality.

- Solutions for small batch size operations – Easy changeovers from the high-tech pushbutton changeover to quick change no tool technology. Simple systems for operators to understand what to do in a changeover.

- Flexible designs and specifications that cater to multiple product lines, future product modifications and changes, and altered pallet patterns with a customized footprint to optimize floor space.

- Systems that can be integrated with planned or existing equipment such as case erectors, case sealer, labeler, stretch wrapper, or conveyor systems

- Product flexibility – Robots that can case pack rigid and non-rigid containers in a variety of packaging configurations. Single or multiple products picks to improve on package throughput.

- A comprehensive range of robot loading arms that suit specifications for speeds, unit loads, and layout requirements

- Fewer risks of product damage because of the accuracy and control over the acceleration and deceleration of the product through the use of robotics.

- Use of long-lasting, top-quality components that meet different industry specifications for durable and hygienic use

- Conveyors designed to accommodate specific applications including wet and dry needs, and speed.

- Installation of equipment including start-up and training if required

Glass and Plastic Bottle Capabilities

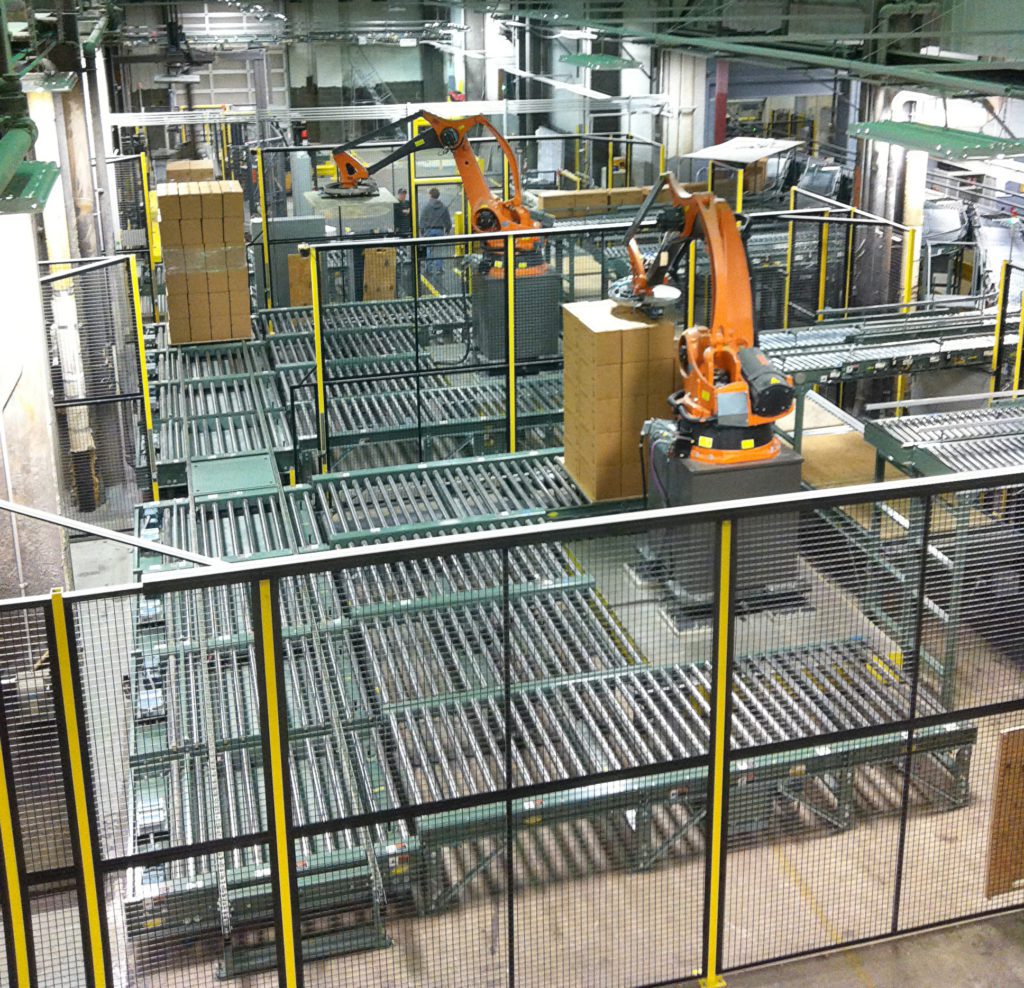

- Robotic bottle palletizers by MESH can easily handle up to four infeed conveyors and their individual SKU and up to four stacking locations in one cell. See our MACPal offering

- Material handling systems from conveyors, lane diverter, bottle turners, accumulation tables, and other systems necessary to prepare the containers for stacking/palletizing are all designed and built in-house at MESH.

- Bottles per minute speed is usually the forefront of most specifications. It is best to consult with MESH sales and applications engineers to understand the productivity needs and options available. Robotic systems with their flexibility can typically perform at 3 – 4 times the rate of an operator and operator in a consistent manner

- Pallet stack height – Most modern palletizing robots if configured correctly can stack up to 108” tall.

- Pallet or stack envelope (length and width) – With a lot of container systems pallet or tray stacks can get as large as 60” square. MESH’s robotic systems can accommodate these larger pallet sizes.

- Dunnage – With automatic slip sheet dispensers and the correct end effector MESH can accommodate most slip sheet requirements. MESH has unique end effectors that can handle the containers and most dunnage without a tool change.

- Safety – MESH designs our robotic case palletizers to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs.

Bottle Palletizing FAQ

Will a custom solution be more expensive than off-the-shelf automated palletizing equipment?

Not necessarily. More importantly, a custom design will meet the needs of your products and maximize the efficiency of the operation, which will ultimately impact positively on your budget.

Will your palletizing equipment cope with different types and shapes of bottles?

Palletizing units can be designed to handle the full range of glass and plastic bottles including those with thin walls, those that are tapered or not rounded, and all the various neck styles and shapes. Palletizing heads designed for different shapes and sizes of containers include those with gripper tubes, suction plates, as well as universal palletizing heads.

How many bottle layers will a robotic palletizer cope with?

It depends on the design, but a robot could load up to nine layers or 108” by picking and placing pallets, tier sheets, and top frames during the process.