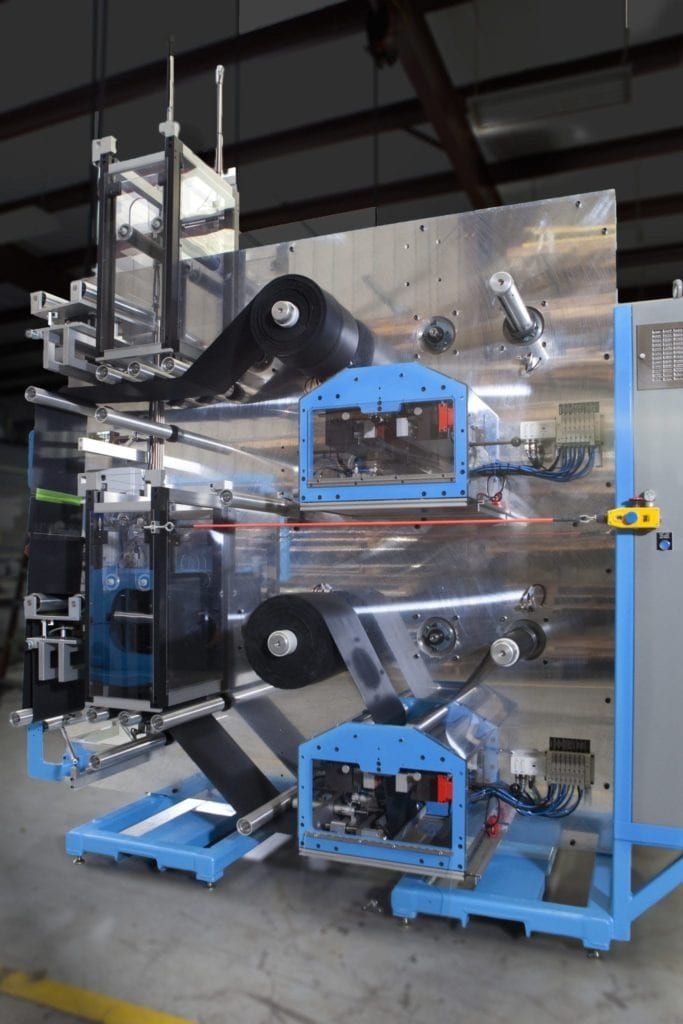

MESH Palletizing Systems for Rolled Goods

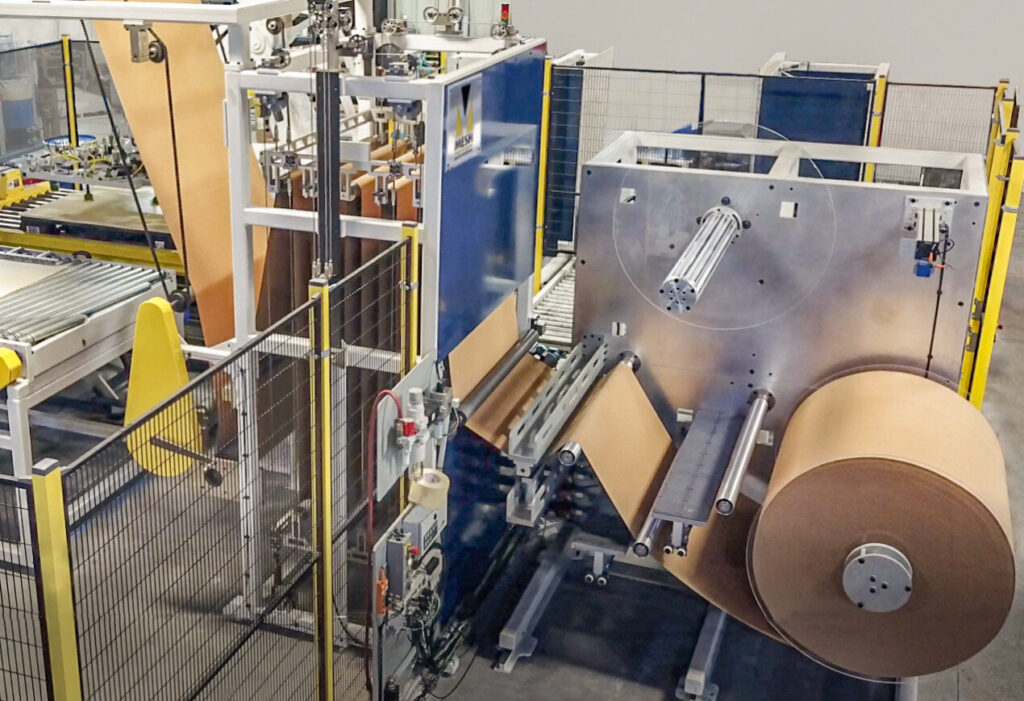

Rolled goods products vary greatly depending on the industry. Yarn, fiber, paper, rolled roofing, stretch wrap, poly, nonwoven, fiberglass, rubber and netting are just some of the forms. Palletizing of these products is typically either eye to the sky or laid flat. Dunnage requirements to keep the rolls steady and apart are also employed in a great many applications.

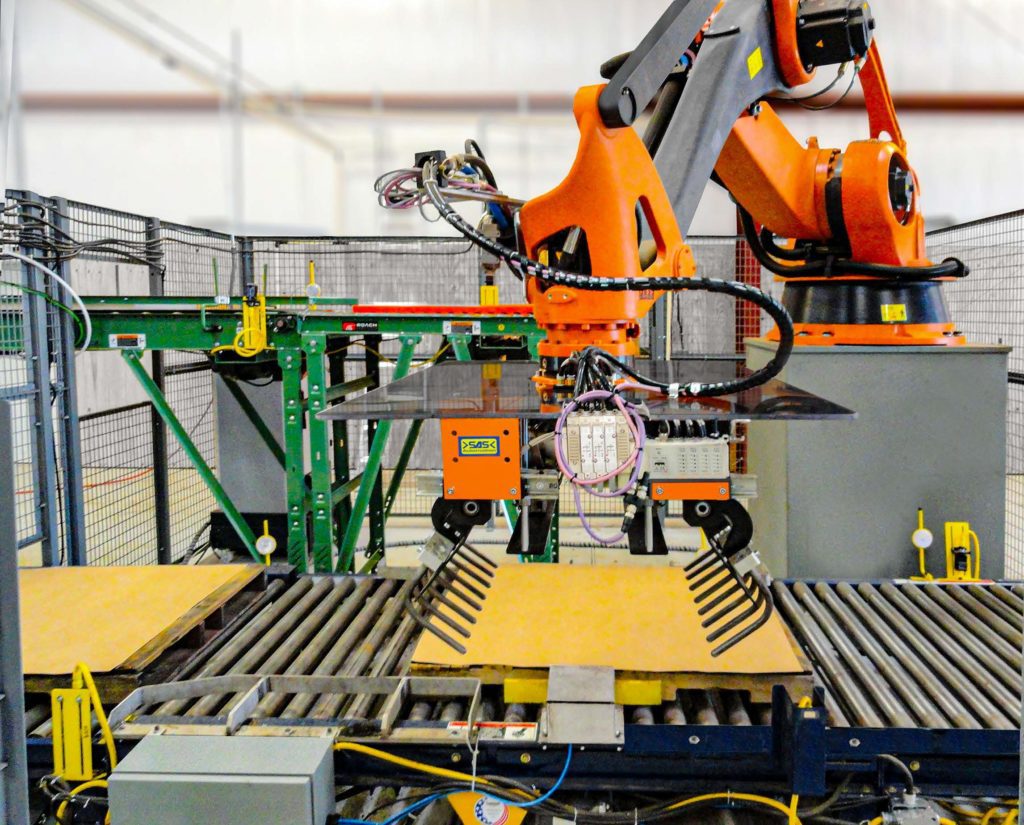

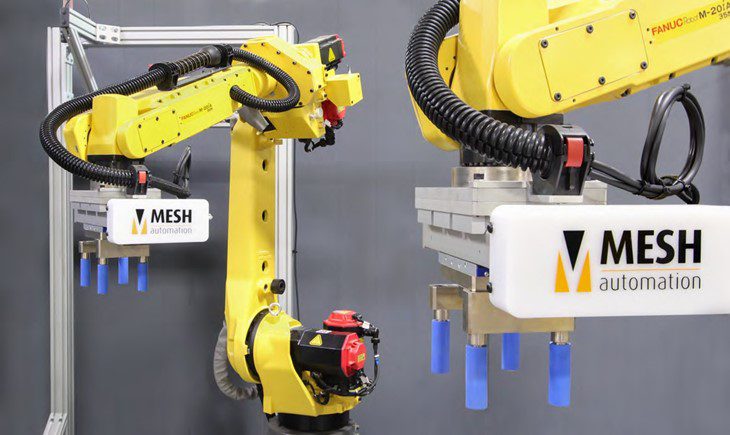

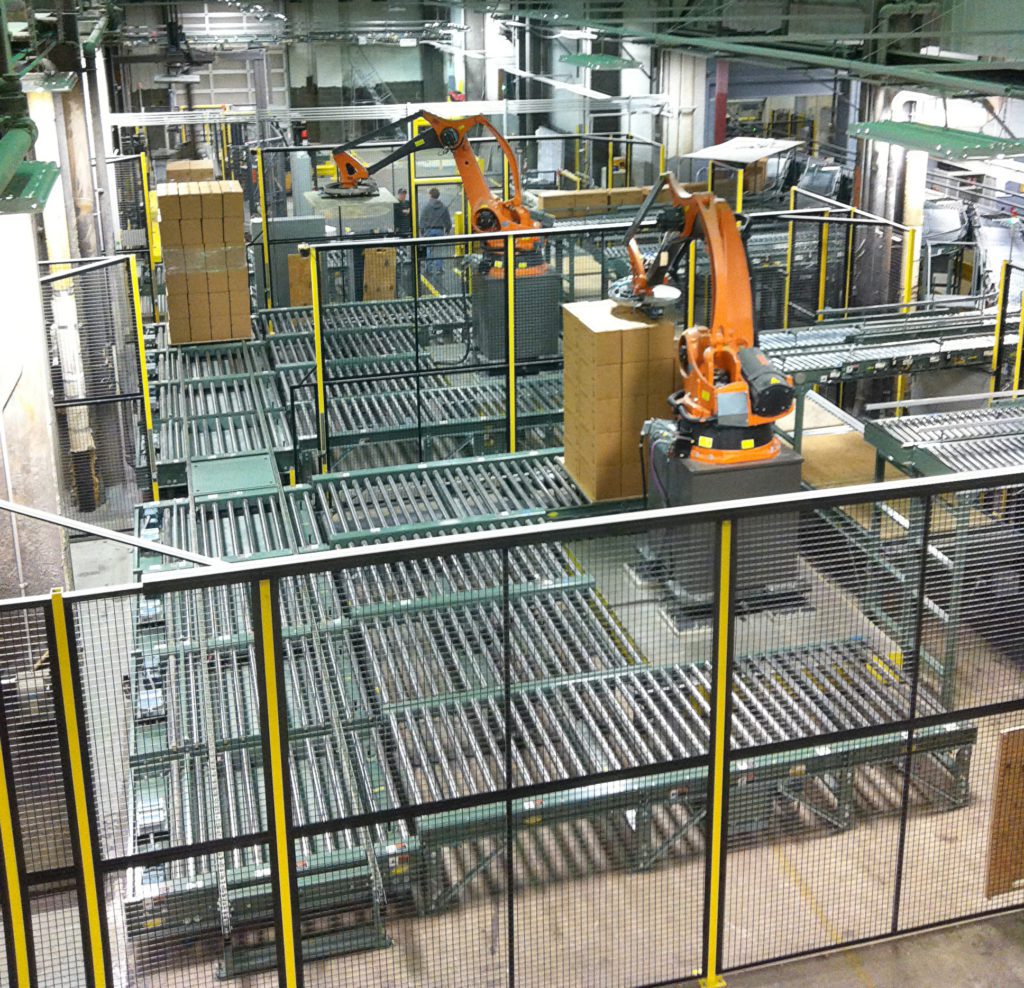

MESH has the proven experience with many of the materials previously mentioned and have installed over 50 robots or cobots in the rolled goods product format. Innovative gripper design to pick up from the core or outside grip rolls that weigh anywhere from 5kg to 250kg are in the experience range of our engineers. This coupled with our proven pallet handling systems and accessories make MESH one of the premier automation suppliers in this category.

Benefits of a MESH designed rolled goods palletizer or handling system

With over 50 robots or cobots employed in handling rolled goods you would be hard pressed to find a more capable supplier than MESH. Over the years we have retrieved, stacked, destacked and automated the dunnage handling of many kinds of rolled goods products. Benefits of automating this process are many fold such as:

- Increase production rates, improve labor utilization, improve job conditions (better ergonomics, less forklift interaction…) reduce product waste and improve product and package quality.

- Cobot solutions on some products help with ergonomics and improved access to the production equipment.

- AMR and AGV interfaces can be easily employed to improve safety, expenses and labor utilization.

- Flexible designs and specifications that cater to multiple product lines, future product modifications and changes, and with customized footprints to optimize floor space

- Systems that can be integrated with planned or existing equipment.

- Product flexibility – Robots are the ultimate flexible automation tool when coupled with excellent and creative tool design.

- A comprehensive range of robot loading arms that suit specifications for speeds, unit loads, and layout requirements

- Fewer risks of product damage because of the accuracy and control over the acceleration and deceleration of the product through the use of robotics.

Capabilities of a MESH designed rolled goods handling system

- Consistent and accurate handling of the product through good tool design and the use of robotics or precision motion control. 1mm accuracy is very feasible.

- Diameter sensor implementation to handle normal variation.

- Speed can vary greatly, but can run as fast as 15 picks per minute for the most efficient layouts and products.

- Dunnage – MESH can accommodate the most common dunnage requirements.

- Automated pallet and product delivery systems can be added.

- Vision and laser dimensional sensing/data can be added to enhance the value of the system.

- Safety – MESH designs our robotic and gantry systems to RIA standards and will complete a risk assessment of the entire system. Our MAC control system uses a safety PLC and high-quality guarding and interlock switches that match the risk assessment’s requirements for modern equipment needs in North America, Asia, or Europe.

FAQs for Rolled Goods Palletizing

Can you combine machine tending with stacking operations?

Yes, in some cases, one robot can be used for both tending the outfeed of a production machine/winder and then stacking that product on a pallet.

Why use a robot for automated rolled goods handling?

Robots have tremendous flexibility and value. Many automation challenges can be solved with the use of robots and deliver good ROI. Robots are durable and can outlast the production equipment in many cases.