Automated Pallet Handling Systems

Automated pallet handling systems consist of equipment that can either stack or destack empty pallets of any size, shape, or material construction and distributes them to a specific location in your manufacturing or warehousing operation.

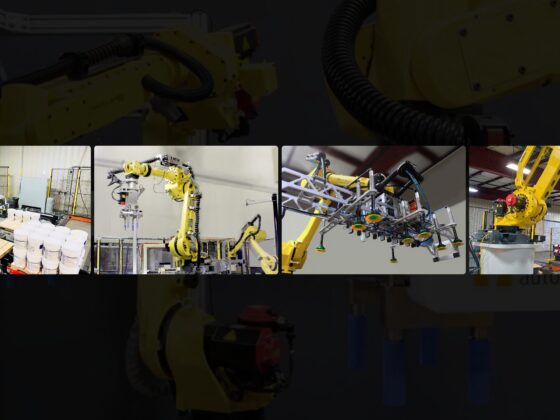

MESH has a complete line of pallet stackers, pallet dispensers, and conveying systems to accomplish the automated pallet handling system you require. Our third generation of pallet dispensers has great value and can be seamlessly integrated into a new or existing conveyor system or work as a standalone system for manual or AGV retrieval of a single pallet. MESH manufactures their automated pallet handling equipment, conveyors and will develop, build and commission the conveyor control system.

MESH also has an adjustable pallet dispenser that can stack or destack standard pallets (48” x 40” GMA) or nonstandard pallets up to 2 meters (80”) wide.

Benefits of Automated Pallet Handling Equipment

When using automated methods the benefits always seem to fall into one or more of the following categories; Automated pallet handling systems are no different. The time to automate has never been greater because the technology is proven and the costs to complete projects typically have great returns on their investment.

- Improved labor utilization

- Reduce injuries

- Improved labor morale and retention

- Reduced variable and fixed costs (waste reduction, reduce material handling costs (forklifts) and others)

- Reduced waste with better efficiency on the manufacturing line

- Improved process control and the resultant improved product quality.

- Better customer retention through a positive impression and controlled process.

- Improved operating hours and throughput

Discussion of Automated Pallet Handling Systems

One critical element of any automated pallet handling system is the pallet dispenser or stacker. Because pallets are not a precise or consistent product, a pallet dispenser design that considers the dimensional and quality variables is important.

Pallet dispensers that can overcome dimensional variables, the occasional nail in the wrong place or broken slat will result in a system that will perform better. Additionally, good sourcing practices (quality and consistent pallets) along with equipment that is rugged and well designed should be your ultimate goal.

MESH’s line of pallet dispensers and pallet stackers meets the ruggedness and design needed to maximize your pallet automation system needs.

Automated Pallet Handling FAQ

What sets MESH’s pallet dispensers apart from the others?

MESH’s pallet dispensers and stackers use heavy gauge full sheet metal weldments with very few openings on three sides to control the stack better than partially open systems. Our pallet lift plates have double the power needed to overcome most obstructions like nails or broken wood that occasionally are in the way. The pallet chain conveyor is integrated in the design with heavier than needed chain models and chain guides. MESH’s pallet equipment also has a plc and real control panel for easier integration to other equipment and safety. Design and ruggedness set MESH equipment apart from the rest.